Residue analysis workflows are common in a variety of laboratory and clinical settings. These workflows include testing for pesticides, antibiotics, fungicides, heavy metals, and a variety of other chemical or biological contaminants. Residue analysis is crucial in protecting our environment, in public health, and in agricultural markets. Before these labs can directly test samples for contaminants, the samples must be processed so residues are first extracted. Then the post-extraction cleanup allows the removal of co-extracted contaminants to enable effective analysis without risk to expensive analytical equipment.

While many post-extraction cleanup methods exist, gel permeation chromatography (GPC) is a great way to remove high molecular weight contaminants from samples before analysis. In this article, we examine the principles behind GPC, the components of a GPC system, and the GPC process.

What is Gel Permeation Chromatography?

Gel permeation chromatography is a chromatographic method that separates compounds in a solution by size. It’s also known as size exclusion chromatography (SEC) or gel filtration chromatography.

In post-extraction cleanup, GPC is used to remove high molecular weight substances (ex, fat, protein, pigment, plasticizer) after extraction and before analysis by GC, HPLC, GC/MS, and LC/MS. Removing these substances with GPC prevents damage to downstream instruments and columns and ensures that no other compound interferes with analyte detection.

How does GPC Size Separation Work?

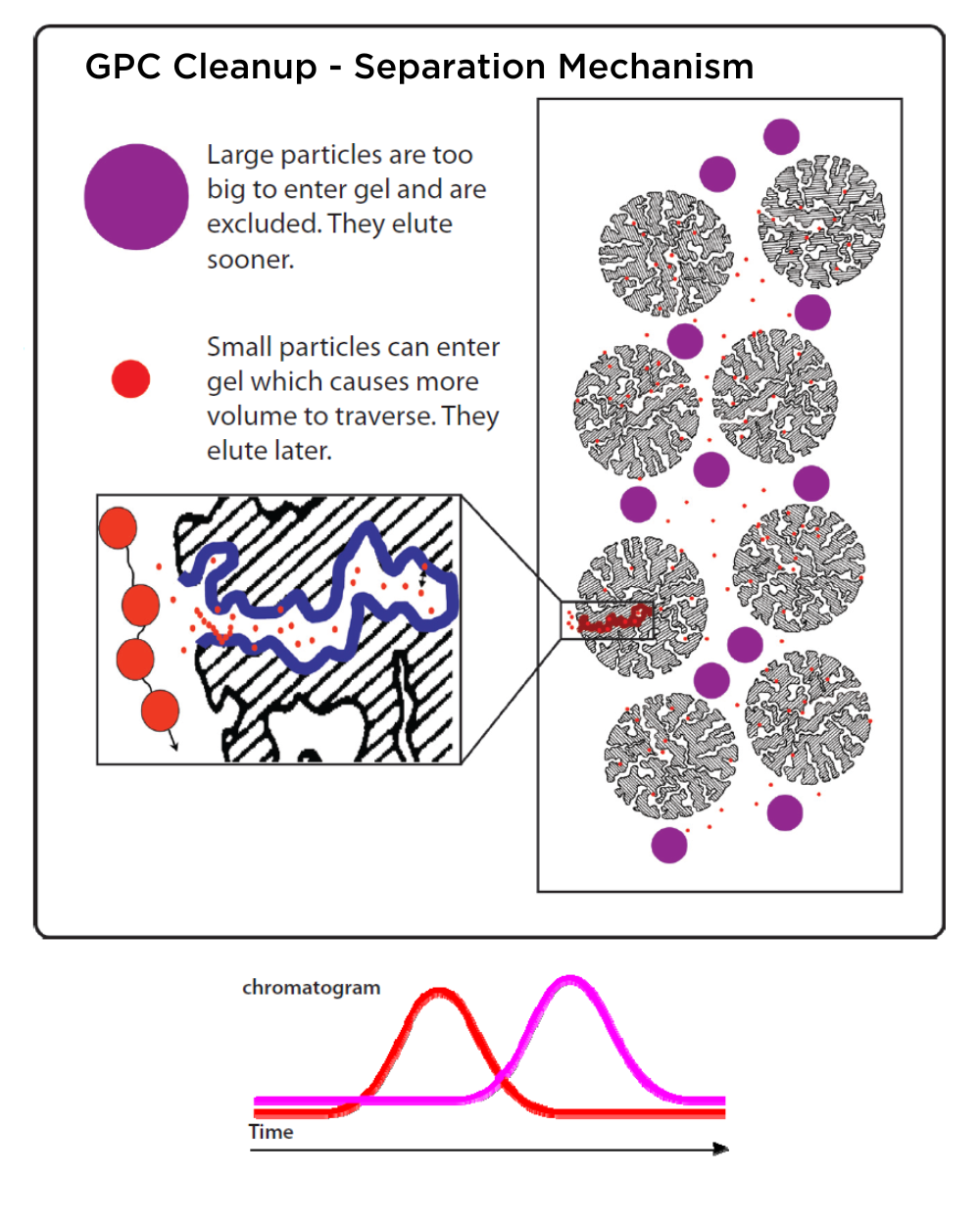

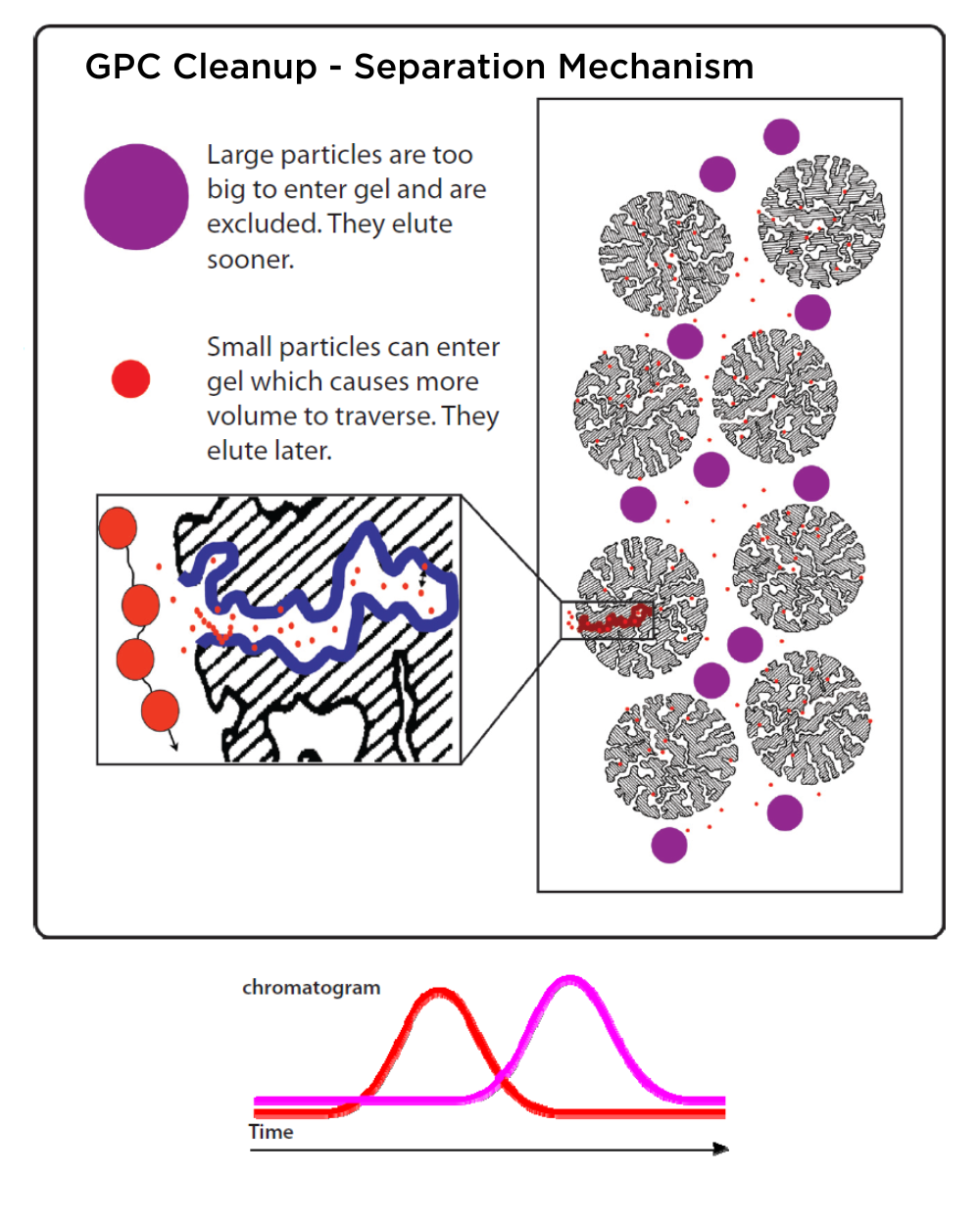

GPC size separation uses a matrix of particles to separate large and small molecules (Figure 1). High molecular weight material is not retained by the matrix and elutes faster than lower molecular weight substances. Because of their small size, low molecular weight substances travel through pores within the particles and, therefore, travel more distance through the column. These molecules elute later than high molecular weight substances that bypass these pores. Typically, the analyte of interest is collected in a single fraction after the high molecular weight contaminants elute.

Figure 1. In GPC, large particles are too big to enter the matrix and elute earlier. Small particles enter the matrix and travel a greater distance. These particles elute later as shown on the chromatogram.

Components of a GPC System

A GPC system consists of the following components:

- • An isocratic pump that pumps solvent typically at a flow rate of 2-5 ml/min through the system. It’s important for the pump to deliver solvent at a constant rate.

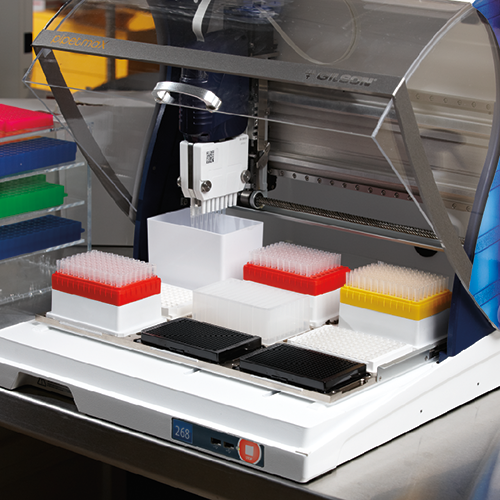

- • An injector that introduces the sample (usually in a volume of 1-5 mL) into the system. This can be automated using an autosampler (ex: VERITY® GX-271 Liquid Handler).

- • A column that contains the size exclusion media used to separate components of the sample. Typically, the columns contain porous cross-linked polymer material such as cross-linked styrene divinylbenzene polymer beads and can have various particle diameters and pore sizes. When choosing a column, take into consideration the molecular weight range you are trying to separate, the pore size of the column, and whether this is appropriate for your molecular weight range, solvent compatibility with your sample and with the column material, and column volume

- • An optional UV detector. This requirement is different based on the guidance from regulatory agencies. The detector is usually used to control columns and elution time windows.

- • A fraction collector that collects the eluted analyte of interest. Usually, one fraction is collected per sample.

The GPC Process: Step by Step

1. Sample prep and calibration: Samples are prepared by dissolving them in an appropriate solvent, either an organic solvent or an aqueous solvent, based on the sample type. Depending on the sample, it can take several hours to completely dissolve. The final sample concentration should be less than 1% weight/volume but can vary depending on sample type and sample molecular weight. Once dissolved, sample extracts are filtered and placed into sample vials.

Before running the sample on the column, calibrate the column if needed. Calibration is typically done once a week. The calibration uses molecular weight standards to generate a calibration curve plotting retention time vs. molecular weight. This calibration curve can be used to determine the retention time for fraction collection.

2. Equilibration: To equilibrate the column, flush it with the solvent used to dissolve the sample. This is commonly an organic solvent such as dichloromethane at a flow rate of 5 mL/min (USEPA methods) or a 1:1 ratio of ethyl acetate and cyclohexane at a flow rate of 2-5 mL/min (EU).

3. Load sample: The sample can be manually injected or injected with an autosampler.

4. Separation and elution: Once in the column, the molecules separate based on size. When they exit the column, a detector (if used) monitors the elution and displays it in a chromatogram.

5. Fraction collection: High molecular weight materials, such as lipids, elute first and are discarded to waste. The fraction containing the analyte of interest is collected into a large vessel on a collection tray for further processing. Late-eluting fractions, such as sulfur and soil or sediment extracts, can be directed to waste after collecting the compounds of interest.

6. Regenerate column: Flushing the column with the elution solvent removes any residual sample so that the column can be reused for subsequent separations.

7. Analysis: The collected fraction should be analyzed to quantify and confirm the target compound. The calibration curve can help calculate the molecular weights of the separated sample.

Advantages of GPC for Post-extraction Cleanup

There are many approaches to post-extraction cleanup, including those that are less instrument intensive, such as those based on dilution, filtration, or partitioning using an organic solvent or salts, and other chromatography-based methods, such as solid phase extraction (SPE).

However, GPC has the following advantages:

- • A “universal” cleanup method as contaminants separate by size rather than properties that may be specific to only a subset of molecules

- • Effective for polar and non-polar analytes

- • Non-destructive and non-adsorptive, meaning that you don’t lose part of your sample

- • GPC columns are reusable and have a long lifetime

- • Compatible with a wide range of organic solvents

- • Analytical integrity is maintained - no alteration of isomer ratios

- • Amenable to automation

Flexible Post-extraction Cleanup With Gilson’s GPC System

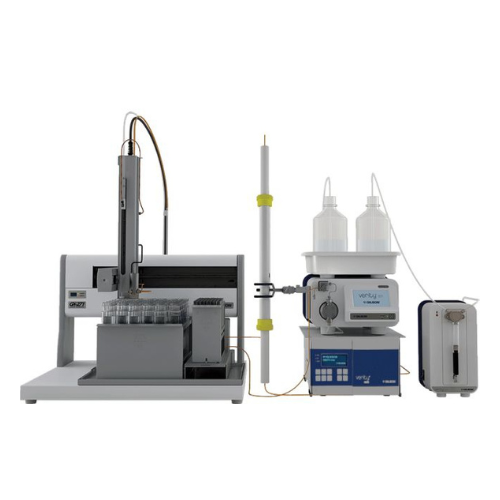

GPC cleanup is a simple and economical manual method that benefits from automation to free up laboratory staff and reduce chemical exposure to users. Gilson’s VERITY® GPC Cleanup System is an automated system that simplifies the cleanup of up to 80 sample extracts. This system is controlled by TRILUTION® LC Software so you can choose preprogrammed GPC methods to make the process even easier. The VERITY® GPC Cleanup System can be configured with and without a UV detector to meet various GPC post-extraction regulatory guidelines.

VERITY® GPC Cleanup System with VERITY® 1741 UV-VIS Detector

As we find new ways to grow food, clean our water supply, and identify new pathogens, it is increasingly important to make sure your application is accurate and optimized to ensure quality, nutritious food and a safe environment for us to live in. From analyzing pesticides on crops to identifying perfluorinated compounds in water, your food safety and environmental applications can benefit from Gilson’s range of extraction and liquid handling solutions.

LEARN MORE